JEOL Cross Section Polisher IB-19510CP

Cross Section Polisher IB-19510CP

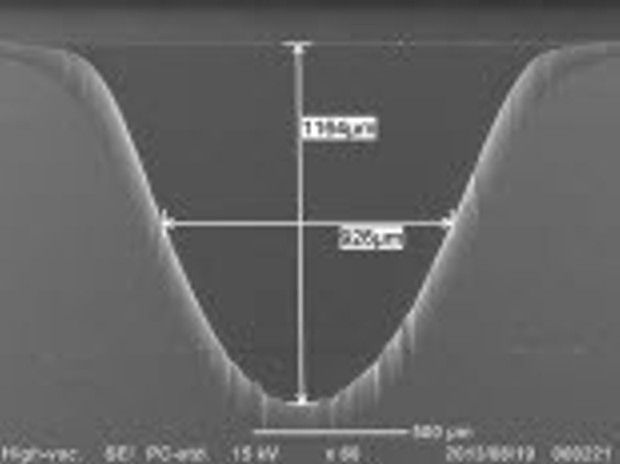

The JEOL Cross Section Polisher IB-19510CP is an easy-to-operate preparation system for the production of specimen cross-sections for SEM, EPMA and auger applications. Soft, hard and composite materials can be prepared with a minimum of specimen damage, deformation and smearing. New high-speed and fine milling modes achieve even higher throughput of high-quality cross sections.

Intermittent milling mode is standard, simplifying the handling of specimens susceptible to heat damage.

Features

Improvements to facilitate fast and easy processing of a wide range of materials include:

- High-speed processing achieved with a new ion source

- Reduced specimen damage with fine milling & intermittent mode

- A Quick Start function reduces total process time

- A monitor camera is standard, allowing real-time monitoring of the milling process

- Charge preventive IN-situ coating function (option)

New high-speed ion source

Delivers 500μm/h

(8kV/2 hour average)

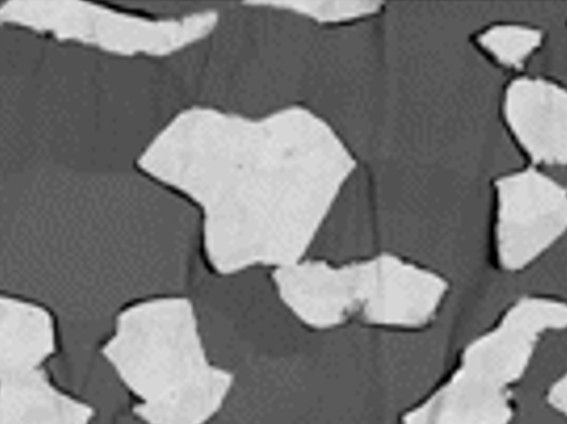

Selectable finishing

By setting the fine milling parameters after high-speed processing ion damage to the cross section can be reduced.

Damage reduction with intermittent mode

Intermittent milling mode is standard, allowing heat damage of specimens to be reduced

Process monitor function

The process of the cross section can be monitored in real-time by a CCD camera. It is even possible to vary the magnification.

Charge prevention IN-situ coating function (Option)

Thin high quality carbon coating is possible, ideal for EBSD and EDS element analysis of non-conductive specimens.

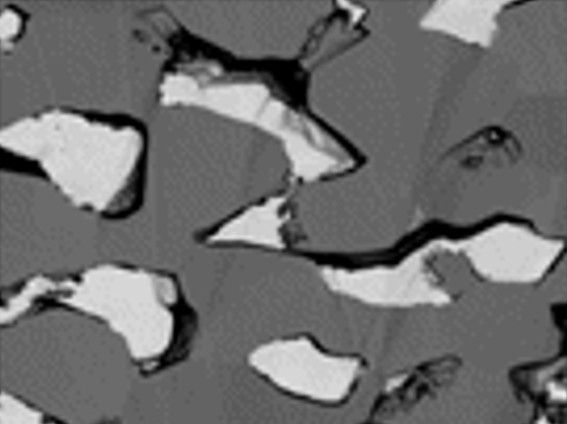

Rotation specimen holder (Option)

The holder that allows ion beam milling while the specimen is rotated.

Both cross-section and surface milling can be performed.

It is suitable for specimens prone to artifacts, such as porous materials, powder, and fibers.

It is ideal for finishing to remove milling distortion.

Specifications

Ion accelerating voltage | 2 to 8kV |

Ion-beam diameter | 500μm (full width at half maximum) |

Milling speed | 500 μm / h (average speed in 2 hours at 8 kV, Si, Distance to edge: 100 μm) |

Maximum specimen size | 11 mm (W) × 10 mm (D) × 2 mm (H) |

Specimen movement stage | X: ± 10 mm, Y: ± 3 mm |

Specimen-rotation adjustment range | ±5° |

Swing specimen | Specimen swings 30 degrees during milling |

Operation | 165 mm touch panel display |

Gas for ion beam | Argon |

Pressure monitor | Penning gauge |

Pumping system | TMP, RP |

Dimensions and weights | Main console: |

| Installation Requirements | |

|---|---|

Power | Single-phase AC 100 to 120 V 10%, 50/60 Hz, 0.5 to 0.6 kVA |

Grounding | 100 Ω or less |

Argon gas | Pressure: 0.15±0.05 MPa (1.0 to 2.0 kg/cm²) |

Room temperature | 15 to 25° C |

Humidity | 60% or less |

Please note:

Subject to technical changes; errors excepted. All brand names that appear in the text are registered trademarks of the manufacturers.